Ferodo Racing Front Brake Pads FCP399 For LAMBORGHINI Contach S Quattrovalvole 1985-1991

141,86€ – 169,38€ WITH TAX

Ferodo Racing Front Brake Pads FCP399 For LAMBORGHINI Contach S Quattrovalvole 1985-1991

Compatable With: ATE Calipers.

SKU: FCP399-7791

Category: Ferodo Racing Brake Pads

Tags: Brake Pads, Ferodo, Front, LAMBORGHINI, Racing

Ferodo Racing Front Brake Pads FCP399 For LAMBORGHINI Contach S Quattrovalvole 1985-1991 FCP399H

Compatable With: ATE Calipers.

BRAKE PADS

Ferodo Racing offers one of the most extensive ranges of brake pad shapes in the racing and high-performance brake market. This broad fitment range is available with various compounds, allowing drivers to choose the ideal option based on their application and personal preference.

Each compound is clearly identified by a unique suffix, such as DS2500 with the suffix H, helping you easily select the right pad for your needs. If the suffix includes a “B” (e.g., GB), it means the pad set has undergone a high-temperature heat-soak during production, allowing for faster bedding and improved performance right from the start.

Compounds

DS2500 (H)

PRODUCT CODE: FRP/FCP****H

MAIN APPLICATIONS: Track day, light race use, Rear GT

MAIN FEATURES

• Road style refinement but with race material ability to withstand heat with respect to life and µ

• Applications: track day & light race use for all vehicle types

• Average friction coefficient of 0,41 over working temperature range of 0° - 500° C

WARNING: DS2500 DOES NOT HAVE R90 CERTIFICATION AND SO IT IS NOT RECOMMENDED FOR ROAD USE IN THOSE COUNTRIES WHICH REQUIRE R90

MAIN APPLICATIONS: Track day, light race use, Rear GT

MAIN FEATURES

• Road style refinement but with race material ability to withstand heat with respect to life and µ

• Applications: track day & light race use for all vehicle types

• Average friction coefficient of 0,41 over working temperature range of 0° - 500° C

WARNING: DS2500 DOES NOT HAVE R90 CERTIFICATION AND SO IT IS NOT RECOMMENDED FOR ROAD USE IN THOSE COUNTRIES WHICH REQUIRE R90

DSUNO (Z/ZB)

PRODUCT CODE: FRP/FCP****Z/ZB

MAIN APPLICATIONS: Rally, Rear GT, Formula, Track car with OE brakes

MAIN FEATURES

• Heavy duty semi-endurance material

• Very controllable torque output

• Very kind to discs

• Long life

• Applications: touring car, GT, single seat, rally

• Average friction coefficient 0.48 over working temperature range of 200°-750°C

WARNING: DSUNO IS NOT SUITABLE FOR ROAD USE

MAIN APPLICATIONS: Rally, Rear GT, Formula, Track car with OE brakes

MAIN FEATURES

• Heavy duty semi-endurance material

• Very controllable torque output

• Very kind to discs

• Long life

• Applications: touring car, GT, single seat, rally

• Average friction coefficient 0.48 over working temperature range of 200°-750°C

WARNING: DSUNO IS NOT SUITABLE FOR ROAD USE

TL66 (TL66)

PRODUCT CODE: FRP****TL66

MAIN APPLICATIONS: GT, Rally, TC, Formula, heavy duty track use

MAIN FEATURES

• High friction coefficient and high initial bite, similar to DS3.12 but with less torque build-up during the stop for enhanced controllability

• ABS compatible

• Together with DS3.12 it has the longest pad life of the Ferodo Racing range under heavy duty track use

• Applications: recommended for track use on larger vehicles with ABS such as GT4 and GT3 and also works well in rally

• Reproducible and stable performance up to 800°C under all pressure and speed conditions

• It has been used at the Nürburgring and SPA 24 hour events

WARNING: TL66 IS NOT SUITABLE FOR ROAD USE

MAIN APPLICATIONS: GT, Rally, TC, Formula, heavy duty track use

MAIN FEATURES

• High friction coefficient and high initial bite, similar to DS3.12 but with less torque build-up during the stop for enhanced controllability

• ABS compatible

• Together with DS3.12 it has the longest pad life of the Ferodo Racing range under heavy duty track use

• Applications: recommended for track use on larger vehicles with ABS such as GT4 and GT3 and also works well in rally

• Reproducible and stable performance up to 800°C under all pressure and speed conditions

• It has been used at the Nürburgring and SPA 24 hour events

WARNING: TL66 IS NOT SUITABLE FOR ROAD USE

FER4003 (C)

PRODUCT CODE: FRP/FCP****C

MAIN APPLICATIONS: Formula, Rear TC

MAIN FEATURES

• Light/medium duty race material specifically for Formula cars, occasional rally

• Very short bedding time

• Excellent bite

• Low drag and excellent release

• Offers control to avoid wheel lock when downforce reduces

• Average friction coefficient 0.46 over working temperature range of 100° - 550° C

WARNING: FER4003 IS NOT SUITABLE FOR ROAD USE

MAIN APPLICATIONS: Formula, Rear TC

MAIN FEATURES

• Light/medium duty race material specifically for Formula cars, occasional rally

• Very short bedding time

• Excellent bite

• Low drag and excellent release

• Offers control to avoid wheel lock when downforce reduces

• Average friction coefficient 0.46 over working temperature range of 100° - 550° C

WARNING: FER4003 IS NOT SUITABLE FOR ROAD USE

TL180

PRODUCT CODE: FRP****TL180

MAIN APPLICATIONS: GT, heavy duty track use

MAIN FEATURES

• Highest friction coefficient in Ferodo’s heavy-duty range

• ABS compatible

• Reduces disc peak temperatures

• Applications: recommended for track use on heavy high-powered cars such as GT3, GT2, sprint and endurance duration races

• Reproducible and stable performance up to 850°C under all pressure and speed conditions

WARNING: TL180 IS NOT SUITABLE FOR ROAD USE

MAIN APPLICATIONS: GT, heavy duty track use

MAIN FEATURES

• Highest friction coefficient in Ferodo’s heavy-duty range

• ABS compatible

• Reduces disc peak temperatures

• Applications: recommended for track use on heavy high-powered cars such as GT3, GT2, sprint and endurance duration races

• Reproducible and stable performance up to 850°C under all pressure and speed conditions

WARNING: TL180 IS NOT SUITABLE FOR ROAD USE

DS3.12 (G/GB)

PRODUCT CODE: FRP/FCP****G/GB

MAIN APPLICATIONS: GT, V8, Stock Car, heavy duty track useMAIN FEATURES• High friction coefficient and high initial bite• ABS compatible• Applications: recommended for track use on larger vehicles with ABS such as GT4 and GT3, sprint and medium duration races (up to 6 hours)• Reproducible and stable performance up to 850°C under all pressure and speed conditions

WARNING: DS3.12 IS NOT SUITABLE FOR ROAD USE

WARNING: DS3.12 IS NOT SUITABLE FOR ROAD USE

DS1.11 (W/WB)

PRODUCT CODE: FRP/FCP****W/WB

MAIN APPLICATIONS: Formula, Rear TC-GT, Track car with OE brakes

MAIN FEATURES

• Heavy duty endurance material

• Long life

• Very kind to discs

• Applications: touring car, GT, single seat

• Average friction coefficient 0.46 over working temperature range of 200°-750°C

WARNING: DS1.11 IS NOT SUITABLE FOR ROAD USE

MAIN APPLICATIONS: Formula, Rear TC-GT, Track car with OE brakes

MAIN FEATURES

• Heavy duty endurance material

• Long life

• Very kind to discs

• Applications: touring car, GT, single seat

• Average friction coefficient 0.46 over working temperature range of 200°-750°C

WARNING: DS1.11 IS NOT SUITABLE FOR ROAD USE

DS3000 (R)

PRODUCT CODE: FRP/FCP****R

MAIN APPLICATIONS: TC, Rally, Formula, Track car with OE brakes

MAIN FEATURES

• Heavy duty all-round material choice

• Short bedding time

• Applications: touring car, rally, Group N, single seat, hill-climb

• Average friction coefficient 0.48 over working temperature range of 200°-650°C

WARNING: DS3000 IS NOT SUITABLE FOR ROAD USE

MAIN APPLICATIONS: TC, Rally, Formula, Track car with OE brakes

MAIN FEATURES

• Heavy duty all-round material choice

• Short bedding time

• Applications: touring car, rally, Group N, single seat, hill-climb

• Average friction coefficient 0.48 over working temperature range of 200°-650°C

WARNING: DS3000 IS NOT SUITABLE FOR ROAD USE

TL163

PRODUCT CODE: FRP****TL163

MAIN APPLICATIONS: Rear GT & Touring cars

MAIN FEATURES

• TL163 replaces DB

• Low friction coefficient with very flat torque profile

• ABS compatible, minimizing wheel lock-ups and excessive slip towards the end of the stop

• Applications: recommended for track use on rear calipers

• Reproducible and stable performance up to 750°C under all pressure and speed conditions

WARNING: TL163 IS NOT SUITABLE FOR ROAD USE

MAIN APPLICATIONS: Rear GT & Touring cars

MAIN FEATURES

• TL163 replaces DB

• Low friction coefficient with very flat torque profile

• ABS compatible, minimizing wheel lock-ups and excessive slip towards the end of the stop

• Applications: recommended for track use on rear calipers

• Reproducible and stable performance up to 750°C under all pressure and speed conditions

WARNING: TL163 IS NOT SUITABLE FOR ROAD USE

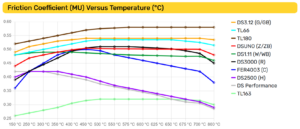

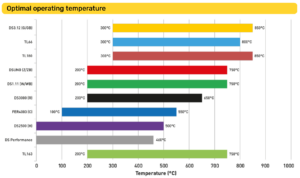

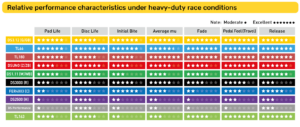

COMPOUND COMPARISON

DISCLAIMER

Ferodo Racing Brake Pads that are labeled for racing use are specifically designed and manufactured for motorsport applications only. These pads are not suitable for road use and must not be used on public roads under any circumstances. The nature of racing, with its inherent risks, prevents Federal-Mogul from guaranteeing or warranting the performance of these brake pads in real-world conditions. Motorsports place unique stresses on components that Federal-Mogul cannot control, and therefore, no warranty is provided for use on public roads.

Warranty and Limitations: Federal-Mogul guarantees that Ferodo Racing Brake Pads are manufactured according to strict specifications and designed to perform within motorsport conditions. However, no warranty is offered for protection against injury or death resulting from their use. By using these racing brake pads, users assume full responsibility for the risks involved.

In addition to the above, except for the express warranty regarding the conformity of the brake pads to manufacturing specifications, Federal-Mogul disclaims any and all warranties, including implied warranties of merchantability or fitness for a particular purpose.

Testing:

All performance and driving results referenced are based on internal and external performance tests, along with recommendations from experienced test drivers.

FEATURES AND BENEFITS

ISO16949 & 14001 Certified Production

All Ferodo Racing brake pads are manufactured to the highest ISO quality standards at Federal Mogul's dedicated manufacturing facility in Italy. With 26 separate quality controls during production, every brake pad is guaranteed to maintain consistent performance and repeatability across all batches.

Precision Engineering

The back-plates of all Ferodo Racing brake pads are made from high-tensile steel, minimizing distortion under the high clamping forces common in motorsport applications. Manufactured with high tolerances, including flatness, parallelism, and overall thickness, these pads ensure a rapid and uniform transmission of pressure from the brake system, enhancing performance and consistency.

Thermal Under-layer

Unlike many competitors, Ferodo Racing brake pads feature a thermal under-layer between the backing plate and friction material. This innovative feature helps to lower brake caliper temperatures by up to 80°C, reducing the risk of brake fluid boiling, which can cause a spongy pedal feel during use.

Disc Friendly

Ferodo Racing brake pads are designed to be gentle on brake discs, optimizing both pad and disc life. Our philosophy is to balance pad durability with minimal disc wear, ensuring the longevity of both components without compromising braking performance.

High Controllability

Ferodo Racing brake pads are engineered to offer a consistent coefficient of friction (µ) across a wide range of temperatures, pressures, and vehicle speeds. This results in a linear brake response, giving drivers a predictable and controlled braking experience.

Wide Range of Material choices and Fitments

With one of the broadest selections of pad shapes in the racing and performance brake market, Ferodo Racing offers a variety of compounds to meet specific needs. Whether you're looking for a solution for track days or high-performance racing, Ferodo Racing brake pads provide the perfect fit for your vehicle and application.

PAD BEDDING

Bedding-in Process for Ferodo Racing Brake Pads

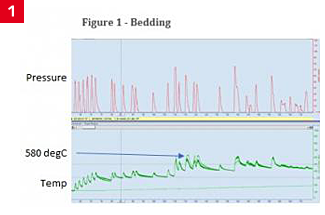

The goal of bedding-in is to gradually bring the brake pads to full race temperatures. Rapid heating can cause glazing, which reduces pad effectiveness. Ideally, the pads should be allowed to cool between bedding and racing, but if time doesn’t permit, the pads can be used immediately with a potential reduction in product life of about 10%.

How to Bed In Ferodo Racing Brake Pads

Follow this process for an effective bedding procedure:

- Initial Application: Perform at least 15 trial brake applications, starting with 50% brake pressure of the normal race conditions. Gradually build up to full deceleration after completing the 15 applications. To save time, apply the brakes on straight sections of the track as well as in corners.

- Target Temperature: Aim for temperatures above 500°C during the bedding process. During the bedding, it’s important to ensure gradual temperature increase to avoid glazing.

- Thermal Treatment Pads: Pads with the part numbers that include WB, ZB, GB, TL180, DB, FB have undergone intense thermal treatment during production. For these, reaching 500°C during bedding is not as critical, and the number of applications can be reduced. Bedding for these compounds primarily serves as a mechanical mating between the pad and the disc.

- Pad Smoking: It is normal for pads to produce smoke during the cool-down phase. For specific compounds like DS1.11, DS3.12, and DSUNO, the temperatures should reach between 500°C and 700°C. You can check this by observing thermal paint on the discs, which should change color completely or partially (from green to orange).

- Cooling Ducts: To achieve the necessary temperatures, it may be necessary to close the cooling ducts during the bedding phase.

- Inspection: After completing the trial applications, allow the pads to cool. Inspect the surface of the brake pads on the two wheels that have experienced the most stress. There should be at least 80% contact coverage without any visible glazing.

After bedding is complete, if time allows, inspect the pads for any visible issues. Ideally, the brake system should be cooled to below 100°C (which might take more than five minutes). Once the system has cooled, your pads will be ready for racing.

Key Tips:

- Follow the gradual bedding process to ensure the pads bed in properly.

- Allow the brake system to cool between bedding and racing whenever possible.

- Ensure no glazing occurs by inspecting the pads after the bedding process.

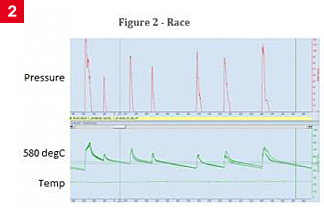

Figure 1: Data from a GT3 car during bedding.

Figure 2: Data from the same car under race conditions (same circuit).

- Red Plot: Brake pressure against time.

- Green Plot: Disc temperature against time.

Figures 3 and 4 below illustrate the appearance of DS3.12 pads that have been properly bedded-in. The pad surface is even, with a dull sheen.

Figure 5 – Example of DS3.12 pad that has not been properly bedded. In this case the final disc temperatures reached were not sufficient and/or insufficient applications were made to allow mechanical mating. In this case pad surface has a non-uniform appearance and these streaks may have a glassy appearance.

| Product manufacturer | FERODO |

|---|---|

| Brand | Brakes |

| Car brand | LAMBORGHINI |

| Ferodo Car Model | CONTACH |

| Ferodo Car Engine | S QUATTROVALVOLE |

| Car year | 1985, 1986, 1987, 1988, 1989, 1990, 1991 |

| Car Year Start | 1985-01-01 |

| Car Year End | 1991-12-31 |

| Position | Front |

| ccm | 5200 |

| Pieces per set | 4 |

| Ferodo KW | 313 |

Only logged in customers who have purchased this product may leave a review.

Related products

-7%

-5%

-5%

-19%

-5%

-19%

-19%

-5%

Bulgarian

Bulgarian Chinese (Traditional)

Chinese (Traditional) Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch English

English Estonian

Estonian Finnish

Finnish French

French German

German Greek

Greek Hungarian

Hungarian Italian

Italian Japanese

Japanese Korean

Korean Latvian

Latvian Lithuanian

Lithuanian Luxembourgish

Luxembourgish Norwegian

Norwegian Polish

Polish Portuguese

Portuguese Romanian

Romanian Russian

Russian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Spanish

Spanish Swedish

Swedish

Reviews

There are no reviews yet.