Eventuri Toyota GR Yaris Carbon Intake – Gloss EVE-GR4-CF-INT

1.623,00€ WITH TAX

Eventuri Toyota GR Yaris Carbon Intake – Gloss EVE-GR4-CF-INT

Toyota GR Yaris

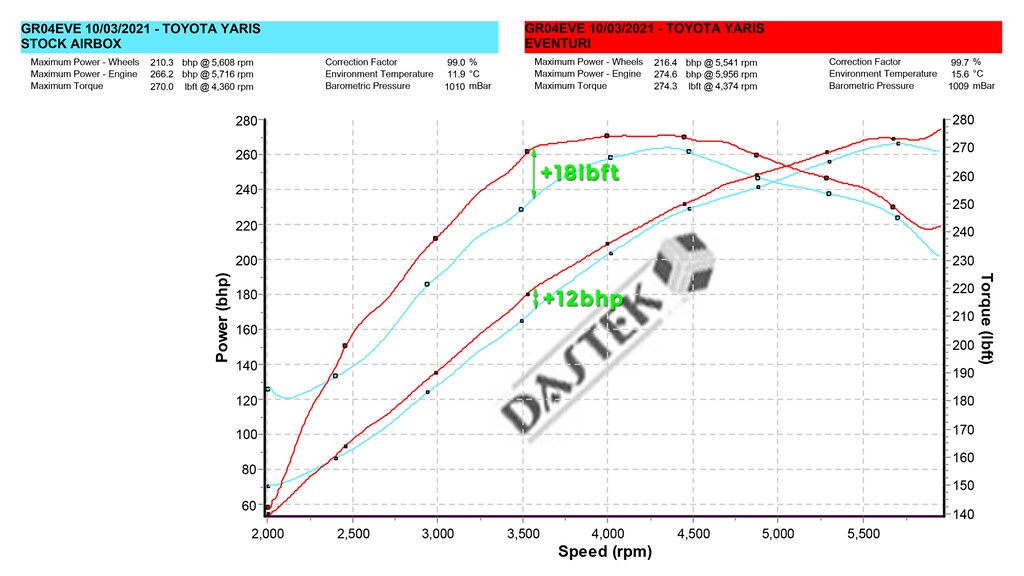

Performance Increase : 15hp, 18ft-lb

*Images show our optional carbon engine cover.

The Eventuri Difference

The GR Yaris Eventuri system uses our Patented Carbon fiber Housing which provides an aerodynamically efficient airflow path from the filter to the turbo. Not just another cone filter with a heat shield but a unique design which invokes the Venturi affect and maintains laminar flow conditions to reduce the drag on the turbo. You can read more about the housing design and how it works HERE.

Delivery time to us: from 1 to 7 working days. Before you order the product, we suggest that you ask for the exact delivery cost and time. The product images shown are for illustration purposes only and may not be an exact representation of the product (contact us for more photos of this product).Eventuri Toyota GR Yaris Carbon Intake – Gloss EVE-GR4-CF-INT

PERFORMANCE

Dyno Testing

Our GR Yaris intake has been tested by various reputable tuners globally who have all reported similar results. The first dyno chart is from RaceCal in the UK. Several runs were done with the OEM airbox to get a repeatable result and then again with the Eventuri intake. Tests were done on the same day back to back with the hood closed. Results show an increase in torque and power across the entire RPM range – not just at the peak RPM, which is why the car feels more responsive and is able to accelerate faster through the gears. The ambient temperatures during this session were 11.9 Deg C for the OEM airbox and 15.6 Deg C for the Eventuri – the rise in temperature was due to the dyno cell warming up after the stock airbox runs.

Dyno Results Summary:

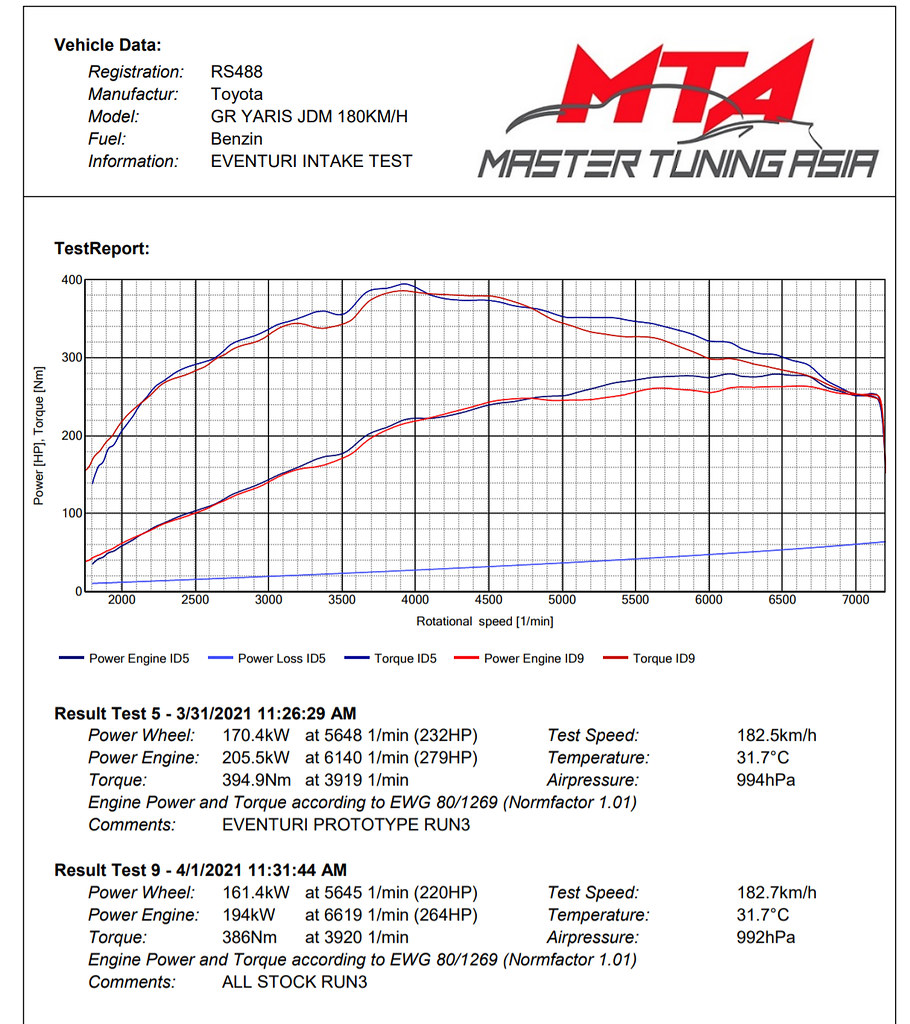

The second set of results are from Master Tuning Asia based in Hong Kong who tested the intake against the stock airbox on the same day and this time in warmer conditions of around 32 Deg C. The systems were tested 3 times and all 3 graphs show gains across the RPM range with the third run showing the highest gain as the stock airbox struggled with the IAT.

MORE DATA TO FOLLOW…

PRODUCT DETAILS

Part Numbers:

- EVE-GR4-CF-INT : Toyota GR Yaris Intake Gloss Carbon

- EVE-GR4-CFM-INT : Toyota GR Yaris Intake Matte Carbon

The Eventuri GR Yaris intake system consists of a number of components engineered to perform a specific purpose and fabricated to the highest of standards. We use 100% pre-preg carbon fiber with no fibreglass which means we can achieve a smooth internal surface to maintain smoother airflow. Here are the details for each component and the design ethos behind them:

Each intake system consists of:

- Carbon Fiber Patented Venturi Filter Housing with integrated MAF section

- Bespoke High Flow Dry Cone Filter

- Carbon Fiber Inlet Duct

- Rear Tube Manufactured To OEM Specifications

- Custom Made Hardware

- Laser Cut Stainless Steel Brackets

- Custom EPDM Hose

- CNC Machined MAF Boss and Bracket Mounts

FILTER HOUSING ASSEMBLY

The filter housing comprises of our bespoke generation 2 filter, aluminium inlet cowl, stainless steel bracket and the integrated MAF section. The carbon pod shrouds the reverse mounted filter and smoothly shapes the airflow down to the MAF section which then connects to the rear inlet tube. This changes the flow path from the OEM airbox where airflow enters the front of the airbox, changes direction by 90 degrees to travel through the panel filter and then changes direction again by 90 degrees to move through the MAF section. Our system is a lot more direct with airflow entering the front of the filter housing and and moving into the MAF section without any abrupt direction changes. The result is a smoother path from the filter to the turbo inlet tube and therefore the turbo is able to function with less drag.

BESPOKE CONE FILTER

In order to achieve the highest flow rate possible we used our largest filter which has an outside diameter of 210mm or 8.3″ and when flow tested with a housing using a 4″ opening is able to flow up to 940 CFM at 28″ H2O. The filter medium is ISO tested to ensure that filtration is in line with OEM standards and is also dry. The filter is constructed with our signature flow cones to aid in the Venturi housing principle.

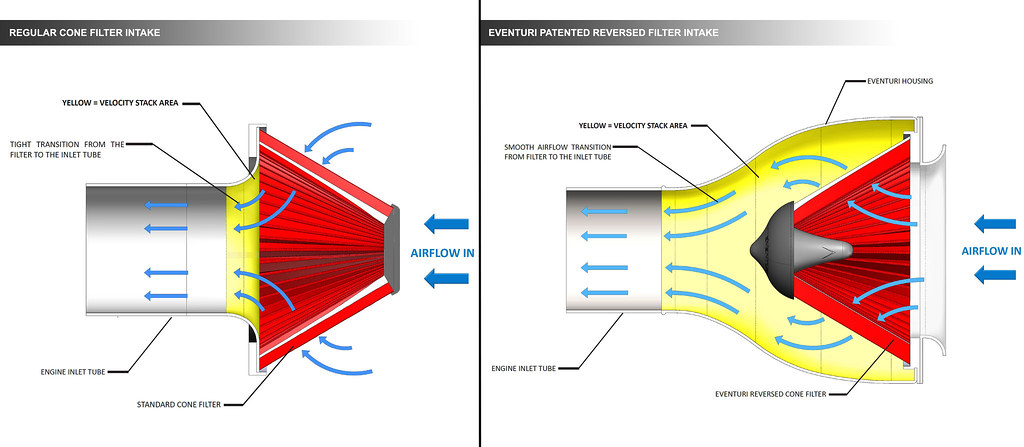

PATENTED TECHNOLOGY

Our patented filter housing has a smooth reduction in cross sectional area as it shrouds the filter and tapers down to the tubing. This geometry invokes the Venturi effect where the airflow accelerates whilst maintaining laminar conditions. It can be thought of as a large velocity stack – below is a diagram to show the comparison between our patented design and a regular intake system. Our bespoke filters aid the airflow moving through the housings and allow for an even velocity profile as the airflow exits the housings. Further details can be read in the Technology and Filters pages.

CARBON DUCT

The duct feeds the filter housing with ambient airflow from the front bumper/grill section. We maintained as large a volume as possible all the way to the front of the engine bay and derestricted the front of the duct by creating an opening just behind the bumper where the bonnet would close. This area of the engine bay stays at ambient temperatures while the car is in motion and so the intake is able to draw in air without being restricted to the small opening behind the grill. We did not extend the duct to the other side of the engine bay to use the second opening in the grill simply because of the abrupt flow angle and the restriction in space between the engine and the bonnet catch. Furthermore, using the second opening would stop cold air from entering the engine bay to assist with reducing overall heat soak. Finally the duct seals against the filter housing with an expanding rubber seal which allows for movement of the filter housing with the engine without letting hot air in.

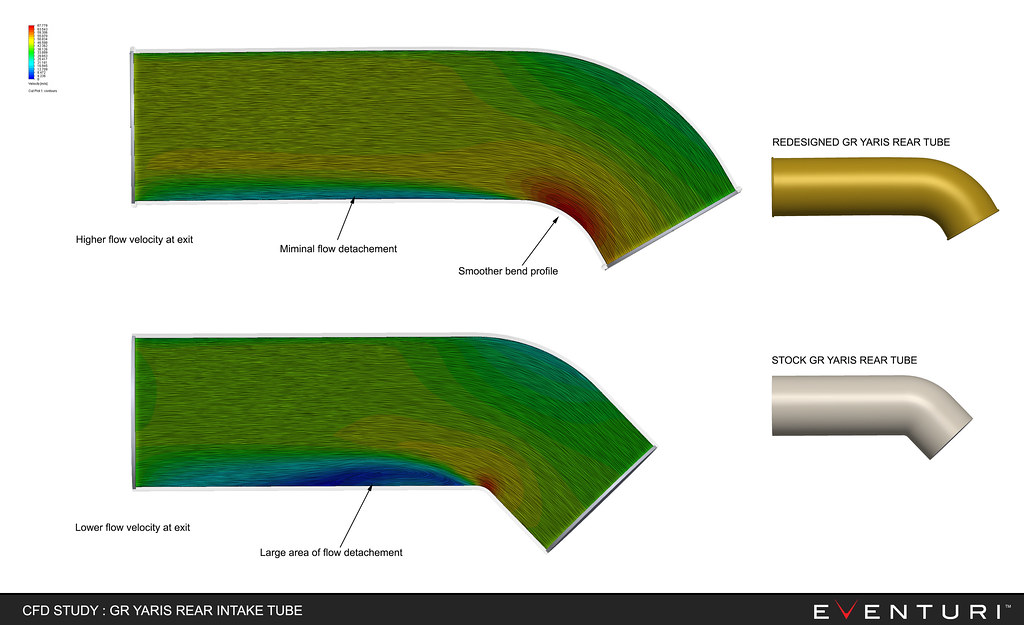

REAR TUBE AND EPDM COUPLER

The final components in the system are the rear inlet tube and the EPDM coupler. The OEM rear tube has a sharp internal bend radius and at high flow rates, this can cause unwanted turbulence which can affect the efficiency of the turbo. We redesigned the rear tube to allow for a smoother bend which also allowed for a more optimum positioning of the filter housing. In order to cope with the heat at the back of the engine, this tube is made from a thermoplastic with glass fiber reinforcement. There is also a CNC machined reinforcement ring at the rear connection where the clamp would be secured. This prevents distortion under heavy clamping pressure – as used in the OEM tube as well. The connection between this tube and the filter housing is achieved with a custom made EPDM coupler which allows for vibrations and movement of the engine.

VIDEO

INSTALLATION GUIDE

Please download here.

| Product manufacturer | EVENTURI |

|---|---|

| Brand | Air Intake |

| Car brand | TOYOTA |

| Eventuri Car Model | GR YARIS |

| Eventuri Filter Type | D |

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.