Eventuri Mercedes A45S CLA45S GLA45 GLB45 AMG Carbon Intake EVE-A45S-CF-INT

1.662,93€ WITH TAX

Eventuri Mercedes A45S CLA45S GLA45 GLB45 AMG Carbon Intake EVE-A45S-CF-INT

Mercedes W177 A45 C118 CLA45

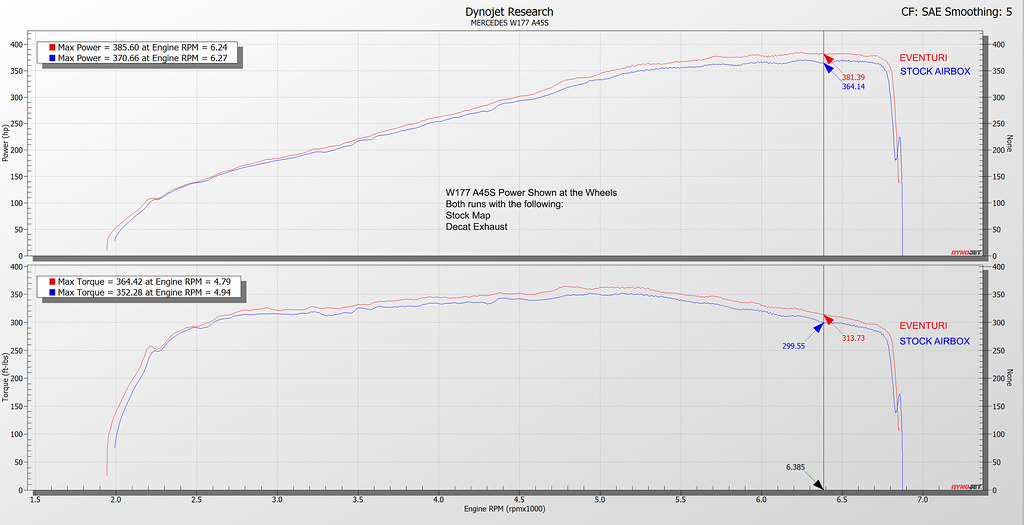

Performance Increase : 15-18hp, 12-16ft-lb

The Eventuri Difference

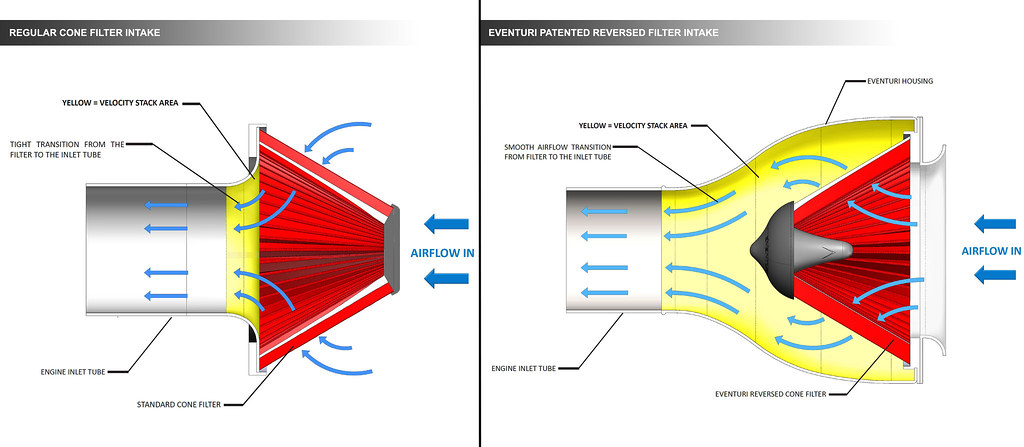

The Mercedes M139 Eventuri system uses our Patented Carbon fiber Housing which provides an aerodynamically efficient airflow path from the filter to the turbo. Not just another cone filter with a heat shield but a unique design which invokes the Venturi affect and maintains laminar flow conditions to reduce the drag on the turbo. You can read more about the housing design and how it works HERE

Delivery time to us: from 1 to 7 working days. Before you order the product, we suggest that you ask for the exact delivery cost and time. The product images shown are for illustration purposes only and may not be an exact representation of the product (contact us for more photos of this product).Eventuri Mercedes A45S CLA45S GLA45 GLB45 AMG Carbon Intake EVE-A45S-CF-INT

PERFORMANCE

Dyno Testing

Our M139 intake has been independently tested by a Mercedes specialist tuner in the UK – MSL Performance. Several runs were done with the OEM airbox to get a repeatable result and then again with the Eventuri intake. Tests were done on the same day back to back. Results show an increase in torque and power across the entire RPM range – not just at the peak RPM, which is why the car feels more responsive and is able to accelerate faster through the gears.

PRODUCT DETAILS

Part Numbers:

- EVE-A45S-CF-INT : Mercedes W177 A45 – C118 CLA45 Intake Gloss Carbon

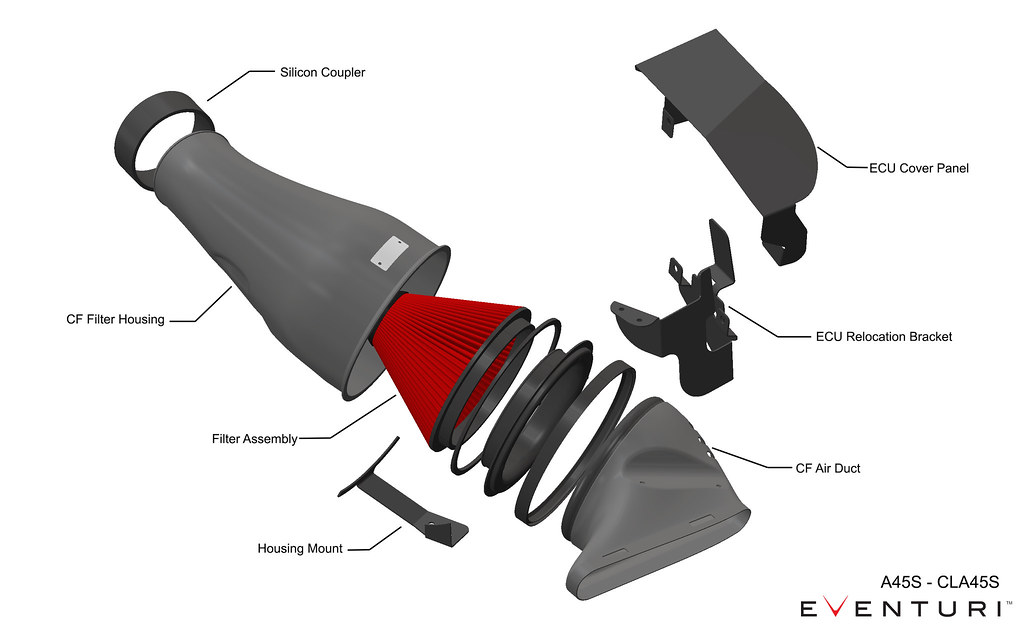

The Eventuri A45/CLA45 intake system consists of a number of components engineered to perform a specific purpose and fabricated to the highest of standards. We use 100% pre-preg carbon fiber with no fibreglass which means we can achieve a smooth internal surface to maintain smoother airflow. Here are the details for each component and the design ethos behind them:

Each intake system consists of:

- Carbon Fiber Patented Venturi Filter Housing

- Bespoke High Flow Dry Cone Filter

- Carbon Fiber Inlet Duct

- Laser Cut Stainless Steel Brackets

- Laser Cut Stainless Steel ECU Relocation Mount

Patented Venturi Filter Housing Assembly

The M139 filter housing comprises of a bespoke high flow filter, aluminium cowl and the carbon pod itself. The carbon pod shrouds the reverse mounted filter and smoothly shape the airflow down to the intake tubes. This smooth reduction in cross sectional area invokes the Venturi effect where the airflow accelerates whilst maintaining laminar conditions. It can be thought of as a large velocity stack – below is a diagram to show the comparison between our patented design and a regular intake system. Further details can be read in the Technology page.

Carbon Fiber Intake Duct

The duct channels ambient air from the slam panel area to the filter housing. It fits inside the OEM ducting system and smoothly transitions to the circular filter housing shape. In order to ensure a good seal against engine bay heat – it also has a flexible rubber edging around the opening which presses against the filter housings creating the desired seal yet allowing the housing to move with the engine. The side of the duct has some cut outs which allow air movement around where the ECU is now relocated to aid with heat saturation. The duct was designed to have the maximum internal volume possible within the given geometry of the engine bay. This ensures that the filter housing is able to draw with minimum restriction.

Laser Cut ECU Relocation Bracket

In order to relocate the ECU we have designed a bracket which is laser cut from stainless steel for strength and rigidity. The ECU securely mounts into this bracket which is then secured to the chassis of the car using the stock locating threads used for the OEM airbox bracket. In addition, there is another bracket which supports the filter housing and finally a piece which covers the top of the ECU to protect the wiring harnesses.

VIDEO

INSTALLATION GUIDE

Please download the guide here.

| Product manufacturer | EVENTURI |

|---|---|

| Brand | Air Intake |

| Car brand | MERCEDES |

| Eventuri Car Model | A45S |

| Eventuri Filter Type | D2 |

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.