Eventuri BMW F9X X5M/X6M, G09 XM, X5/X7 M60i Intake System EVE-X56M-CF-INT

3.044,75€ WITH TAX

Eventuri BMW F9X X5M/X6M, G09 XM, X5/X7 M60i Intake System EVE-X56M-CF-INT

BMW X5M X6M XM

Performance Gain: 18-25hp, 15-18ft-lb with up to 30hp peak gain.

Max Flow Rates: Stock 774 CFM, Eventuri 900 CFM

Fitment : F95 X5M, X6M, G09 XM, X5 M60i

The Eventuri Difference

The F9X X5M, G09 XM Eventuri system uses our Patented Carbon Fiber Housings with our Gen 2 bespoke filters, which provide an aerodynamically efficient airflow path from the filter to the turbos. Not just another cone filter with a heat shield but a unique design which invokes the Venturi effect and maintains laminar flow conditions to reduce the drag on the turbo. You can read more about the housing design and how it works HERE.

Eventuri BMW F9X X5M/X6M, G09 XM, X5/X7 M60i Intake System EVE-X56M-CF-INT

PERFORMANCE

Dyno Testing

This intake has been independently dyno tested by MSL Performance in the UK. Tests were done back to back against the stock airbox and several runs were taken with each configuration. The car tested was without charcoal filters in the stock airboxes. The dyno results show a consistent gain throughout a large part of the RPM range which can be attributed to the turbos reaching peak boost earlier and with a lower wastegate duty cycle due to the higher efficiency of the intake system. The performance gain translates on the road to increased part throttle and full throttle response with the car pulling much more eagerly to the redline.

PRODUCT DETAILS

Part Numbers:

- EVE-X56M-CF-INT : BMW F95 X5M, X6M, G09 XM, X5 M60i Carbon Intake System – Gloss Finish

The Eventuri X5M intake system consists of a number of components engineered to perform a specific purpose and fabricated to the highest of standards. We use 100% pre-preg carbon fiber with no fibreglass which means we can achieve a smooth internal surface to maintain smoother airflow. Here are the details for each component and the design ethos behind them:

Each intake system consists of:

- 2 x Carbon Fiber Patented Venturi Filter Housings

- 2 x Bespoke High Flow Dry Cone Filters

- 2 x Carbon Fiber Twin Air Ducts

- Carbon Fiber Engine Cover

- 2 x EPDM Rear Air Feeds

- Silicon Couplers

- CNC Machined Bracket Mounts

FILTER HOUSING ASSEMBLIES

The filter housings comprise of our bespoke generation 2 filters, aluminium inlet cowls and stainless steel brackets. The carbon pod shrouds the reverse mounted filter and smoothly shapes the airflow down to the OEM turbo inlets. This changes the flow path from the OEM airbox where airflow enters the base of the airbox, changes direction by 90 degrees to travel through the panel filter and then changes direction again by 90 degrees to move through the tube section. Our system is a lot more direct with airflow entering the front of the filter housing and and moving into the turbo inlet section without any abrupt direction changes. The result is a smoother path from the filter to the turbo and therefore it is able to function with less drag.

BESPOKE CONE FILTER

In order to achieve the highest flow rate possible we are using a filter element to make as much use of the space available in the engine bay as possible. The filter medium is ISO tested to ensure that filtration is in line with OEM standards and is also dry. The filter is constructed with our signature flow cones to aid in the Venturi housing principle.

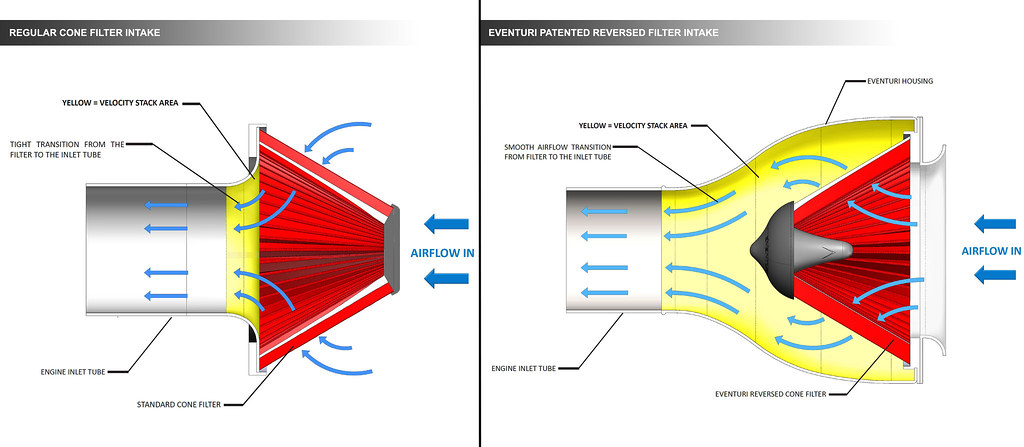

PATENTED TECHNOLOGY

Our patented filter housing has a smooth reduction in cross sectional area as it shrouds the filter and tapers down to the tubing. This geometry invokes the Venturi effect where the airflow accelerates whilst maintaining laminar conditions. It can be thought of as a large velocity stack – below is a diagram to show the comparison between our patented design and a regular intake system. Our bespoke filters aid the airflow moving through the housings and allow for an even velocity profile as the airflow exits the housings. Further details can be read in the Technology and Filters pages.

CARBON TWIN AIR DUCTS

The biggest restriction in the stock system is the location of the feed in comparison to the orientation of the turbo inlets. The feeds are at the front of the car and the turbo inlets face the rear of the car. We have designed the air ducts with an additional opening at the top and introduced a secondary feed where cold air is taken from the scuttle panel. By using both the the OEM air feeds and the additional air feeds, our system is able to flow with a higher rate as well as provide a less tortuous flow path to the turbos.

EPDM REAR FEEDS

To ensure that the intake is fully sealed, the secondary air inlets on the carbon ducts seal to these EPDM feeds which then route to the scuttle panel area. Once the hood is closed, the scuttle area is sealed off from the engine bay therefore these feeds are able to provide the intake with a supply of ambient air. A pre-cut centre section of the OEM hood seal is provided to allow space for these EPDM feeds to be installed.

CARBON ENGINE COVER

Since our filter housings have been designed for maximum volume, the OEM engine cover no longer fits into place. So we have produced a modified cover which finishes off the engine bay, covering the engine hardware for a finished aesthetic. We have allowed for gaps between the engine cover and the intakes so that the heat coming off the engine can easily dissipate rather than soak into the intake system.

The complete system comes together to provide an intake which improves on the stock airbox in performance, aesthetics and sound.

VIDEO

INSTALLATION GUIDE

Please install the guide here.

| Product manufacturer | EVENTURI |

|---|---|

| Brand | Air Intake |

| Car brand | BMW |

| Eventuri Car Model | F9X X5M/X6M |

| Eventuri Filter Type | B |

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.