Eventuri BMW F8X M3/M4 V2 Full Black Carbon intake with SEALED Carbon ducts EVE-F8XMV2-CF-INT

2.894,32€ WITH TAX

Upgrade your BMW F80 M3 & F82/F83 M4 with the Eventuri BMW F8X M3/M4 V2 Full Black Carbon intake with SEALED Carbon ducts EVE-F8XMV2-CF-INT. Designed for optimal airflow and reduced heat soak, this intake system delivers +15-20hp and +18-23ft-lb torque, ensuring faster acceleration and enhanced throttle response. You can read more about the housing design and how it works HERE.

We suggest that you ask for the exact delivery cost and time.

Eventuri BMW F8X M3/M4 V2 Full Black Carbon intake with SEALED Carbon ducts EVE-F8XMV2-CF-INT

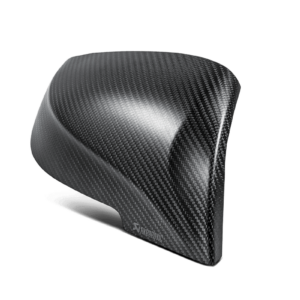

The Eventuri BMW F8X M3/M4 V2 Full Black Carbon intake with SEALED Carbon ducts EVE-F8XMV2-CF-INT represents Eventuri’s commitment to precision engineering and premium materials for your M3 or M4. By utilizing a patented Venturi housing design, it improves airflow while maintaining optimal temperature levels. Crafted from 100% prepreg carbon fiber, this intake system not only provides striking under-hood aesthetics but also delivers consistent performance gains on both road and track.

Unlike standard cone filters with basic heat shields, Eventuri’s unique reversed-filter configuration ensures a smooth flow path. The carbon fiber’s natural insulating properties help reduce heat soak, which is especially critical for the heat-sensitive F80 M4 platform. In doing so, the intake consistently keeps intake air temperature low, ensuring your engine breathes cooler, denser air for noticeable torque and horsepower improvements.

Performance Benefits of the Eventuri BMW F8X M3/M4 V2 Full Black Carbon intake with SEALED Carbon ducts EVE-F8XMV2-CF-INT

On the dyno, this intake system shows gains in horsepower and torque across a broad RPM range—not just at peak. By improving part-throttle and full-throttle response, you will feel quicker acceleration and more enthusiastic pulls to redline. The sealed carbon ducts direct ambient air to the filters, minimizing the entry of heated air from the engine bay. As a result, your M3 or M4 remains more consistent run after run, with reduced heat soak.

Eventuri’s approach balances reduced inlet temperatures with aerodynamic efficiency. Each component, from the bespoke filters to the smooth carbon intake tubes, works in harmony to enhance engine efficiency. The result is a balanced system where you experience enhanced throttle response without compromising on reliability or drivability.

Key Features and Components

Every intake system includes high-flow Gen 2 filters, carbon fiber Venturi housings, and integrated MAF sensor mounts. The short left-side tube and longer right-side tube both utilize carefully engineered transitions to maintain steady airflow velocity. By avoiding abrupt changes in diameter, Eventuri ensures laminar flow, helping the turbochargers draw in air with minimal drag.

- Carbon Fiber Eventuri Housings – Patented design that reverses the cone filter and accelerates airflow smoothly.

- Sealed Carbon Ducts – Channel cooler external air directly into the filters, preventing heat soak.

- Prepreg Carbon Intake Tubes – Feature CNC-machined MAF sensor mounts; shaped to avoid fan shrouds and strut braces without restricting airflow.

- Carbon Air Scoops – Placed behind the front grilles, scoops channel maximum ambient air toward the filters.

Installation and Final Thoughts

Installation of the Eventuri F8X M3/M4 intake system is straightforward thanks to laser-cut stainless steel brackets and OEM-quality couplers. The package includes an easy-to-follow guide, ensuring that enthusiasts and professionals alike can achieve a secure, proper fit.

Overall, the Eventuri BMW F8X M3/M4 V2 Full Black Carbon intake with SEALED Carbon ducts EVE-F8XMV2-CF-INT provides a significant performance upgrade with a refined aesthetic appeal. By reducing intake temperatures, optimizing airflow velocity, and maintaining superior materials quality, Eventuri has created an intake solution that truly complements the engineering excellence of the BMW F8X M3 and M4. Whether you choose the sleek carbon finish or the bold Kevlar variant, you’ll enjoy an invigorated driving experience that showcases Eventuri’s passion for innovation and craftsmanship.

Please download the guide here.

Download Installation Guide

More from Eventuri

| Product manufacturer | EVENTURI |

|---|---|

| Brand | Air Intake |

| Car brand | BMW |

| Eventuri Car Model | F8X M3 / M4 |

| Eventuri Filter Type | S |

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.