Eventuri Toyota GR86 Carbon Intake – Gloss EVE-GR86-CF-INT

1.623,00€ WITH TAX

Eventuri Toyota GR86 Carbon Intake – Gloss EVE-GR86-CF-INT

Toyota GR86

Performance Increase : 10-14hp, 10-11ft-lb

*Images show our optional carbon engine cover.

The Eventuri Difference

The GR86 Eventuri system uses our Patented Carbon fiber Housing which provides an aerodynamically efficient airflow path from the filter to the engine. Not just another cone filter with a heat shield but a unique design which invokes the Venturi affect and maintains laminar flow conditions to reduce the drag on the engine. You can read more about the housing design and how it works HERE.

Eventuri Toyota GR86 Carbon Intake – Gloss EVE-GR86-CF-INT

PERFORMANCE

Dyno Testing – STOCK ECU

Below is a dyno graph of a completely stock GR86 with just the airbox being swapped for the Eventuri intake. This was independently tested at DREAM automotive. Several runs were done with the OEM airbox to get a repeatable result and then again with the Eventuri intake. Tests were done on the same day back to back. Results show an increase in peak torque and power with a “resonance” dip between 5700-6300rpm after which the power gain amounts to 14hp as the curve crosses the stock line and continues to the RPM limit.

Dyno Testing – TUNED ECU

Below is a dyno graph of a GR86 which has been custom tuned by Paragon Performance in the USA. They tuned the car to run E85 with a closed loop fuel control to ensure fueling is identical on both the stock intake and Eventuri to remove the variability of the GR86 open loop fuel control. Paragon also tuned the ECU to eliminate the resonance issue and the results speak for themselves. All runs were carried out with the same tune and only the airbox was changed between runs. Tests were done on the same day back to back.

Dyno Testing – DEVELOPMENT

During development we iterated the intake and tested various configurations to arrive at the optimised version. Over 125 dyno runs were carried out and here is a visual representation of all that data…….

PRODUCT DETAILS

- EVE-GR86-CF-INT : Toyota GR Corolla Intake Gloss Carbon

- EVE-GR86-CF-ENG : Toyota GR Corolla Engine Cover Gloss Carbon

The Eventuri GR86 intake system consists of a number of components engineered to perform a specific purpose and fabricated to the highest of standards. We use 100% pre-preg carbon fiber with no fibreglass which means we can achieve a smooth internal surface to maintain smoother airflow. Here are the details for each component and the design ethos behind them:

Each intake system consists of:

- Carbon Fiber Patented Venturi Filter Housing with integrated MAF section

- Bespoke High Flow Dry Cone Filter

- Carbon Fiber Dual Feed Inlet Duct

- Laser Cut Front Air Scoops

- Custom Made Hardware

- Laser Cut Stainless Steel Brackets

- CNC Machined MAF Boss and Bracket Mounts

FILTER HOUSING ASSEMBLY

The filter housing comprises of our bespoke generation 2 filter, aluminium inlet cowl and the integrated MAF section. The carbon pod shrouds the reverse mounted filter and smoothly shapes the airflow down to the MAF section which then connects to the rear inlet tube. This changes the flow path from the OEM airbox where airflow enters the front of the airbox, changes direction by 90 degrees to travel through the panel filter and then changes direction again by 90 degrees to move through the MAF section. Our system is a lot more direct with airflow entering the front of the filter housing and and moving into the MAF section without any abrupt direction changes. The result is a smoother path from the filter to the turbo inlet tube and therefore the turbo is able to function with less drag. To ensure a reliable seal with the MAF sensor, we use a CNC machined mount secured to the carbon housing.

PATENTED TECHNOLOGY

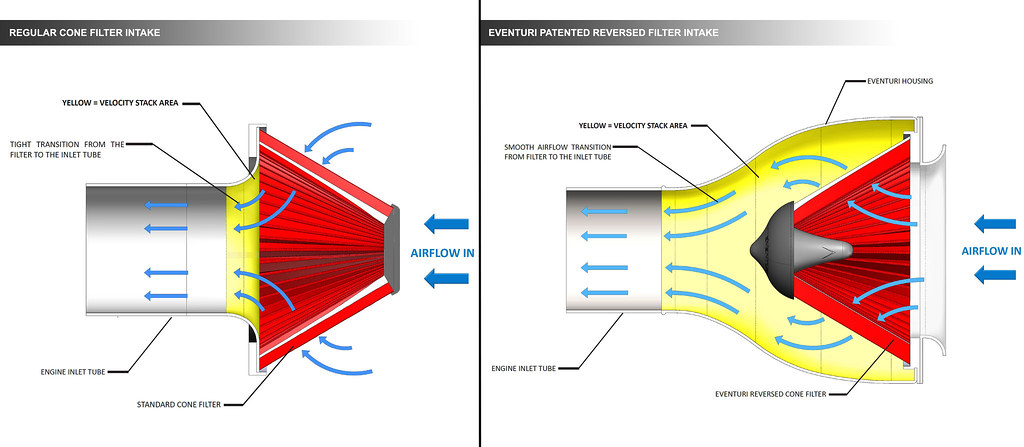

Our patented filter housing has a smooth reduction in cross sectional area as it shrouds the filter and tapers down to the tubing. This geometry invokes the Venturi effect where the airflow accelerates whilst maintaining laminar conditions. It can be thought of as a large velocity stack – below is a diagram to show the comparison between our patented design and a regular intake system. Our bespoke filters aid the airflow moving through the housings and allow for an even velocity profile as the airflow exits the housings. Further details can be read in the Technology and Filters pages.

CARBON DUCT

The duct feeds the filter housing with ambient airflow from the front bumper/grill section. Through testing several iterations we found that a dual intake where cold air was taken from both openings in the slam panel area, functioned in the least restrictive manner. The region in the front bumper area is saturated with cold air from our scoops and also from the natural design of the OEM cavity behind the bumper. The duct has an expanding rubber seal which mates to the filter housing to ensure heated engine bay air is kept away from the intake feed, but still allows for engine movement. It is mounted in 3 positions to ensure a secure fit.

FRONT SCOOPS

The final components are 2 front scoops which sit behind the lower grill to direct ambient air upwards into the opening of the duct. This aids in keeping IATs low while the car is in motion. For owners with aftermarket oil coolers who cannot use the scoops, the IATs will still remain minimal due to the natural saturation of cold air behind the bumper.

| Product manufacturer | EVENTURI |

|---|---|

| Brand | Air Intake |

| Car brand | TOYOTA |

| Eventuri Car Model | GR86 |

| Eventuri Filter Type | S |

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.